Tri Viet

Sharing for Growing together

SYNCHRONOUS PRESTRESSED SHEET PILE TENSION SYSTEM

Post-tensioning sheet piles are widely used for current infrastructure construction projects such as: embankments to protect banks, prevent landslides, embankments of river and sea embankments, irrigation works, wharves, ... Specialized machine system for prestressing of SWPR - 7B steel fibers from Φ12.7mm to Φ15.2mm in diameter. Is a steel system to create stress in production technology of sheet piles and girder. The machine system operates fully automatically by hydraulic system and synchronized on the pedestal from 80m to 140m. Specialized software, allowing direct operation and management of data logs on Computer. The most commonly used machine systems: Tension system

AUTOMATIC PC STEEL CUTTING MACHINE

As the first stage in the production of prestressed concrete, steel is cut from rolled billets which require high precision. As the main factor determining the quality of prestressed concrete products. The machine system operates fully automatically, applying hydraulic technology combined with compressed air through PLC control. Automatic control via specialized software, which allows setting the quantity and length of steel cutting on the LCD screen. Acceptable tolerance reaches ± 1mm / 10,000mm. The most commonly used machine systems: Cutting steel PC Bar, PC Wire Φ5.1mm to Φ10.7mm length 16m serving production: post-tensioning electric post, prestressed square pile, prestressed

PC BAR STEEL HEAD STAMPING MACHINE

PC Bar steel stamping machine is a system of specialized machines for stamping steel oil PC Bar, PC Wire in the production of prestressed concrete structures. PC Bar and PC Wire steel, after being cut according to the specifications, are put into a press machine to form a two-head steel tumor before fastening to the tensioning flanges to create prestress in the prestressed concrete production process. The machine works on the principle of using heat to heat details, then uses hydraulic thrust to form a steel head tumor. The system operates fully automatically, applying hydraulic or pneumatic technology combined

AUTOMATIC STEEL SUPPLYING SYSTEM FOR STEEL HEAD STAMPING MACHINE

It is the perfect automatic combination for PC Bar steel cutting machines and 02 PC Bar steel head stamping machines, which form an automatically combined chain without requiring a worker to operate the machines. Automatic control by specialized software allows setting the quantity and length of steel cutting on the LCD screen.

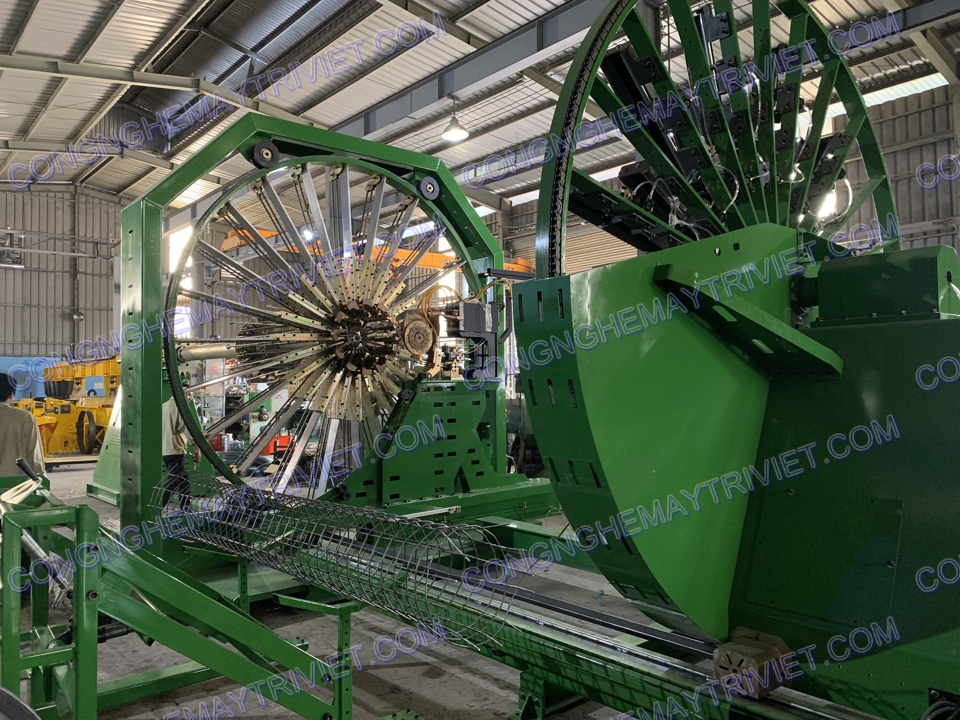

TUBE PILE CAGE WELDING MACHINE

After stamping, the steel is put into the welding machine to shape the steel core for each type of concrete piles. The machine system automatically operates, applying Inverter technology in combination with PLC through specialized software in order to have high economic efficiency and maximize labor savings in the manufacturing process. The most commonly used machine systems: Tube pile cage welding machine specializes in welding PC Bar steel cages to manufacture prestressed centrifugal concrete tube piles of types of D300mm to D600mm with the length up to 18m. Tube pile cage welding machine specializes in welding PC Bar steel

ELECTRIC POLE CAGE WELDING MACHINE

Electric pole cage welding machine specializes in welding and shaping PC Bar steel cages to manufacture prestressed centrifugal concrete electric poles. The machine system is automatically operated, applying Inverter combined with PLC technology through specialized software. The machine manufactures steel cages according to the following standards: Standard electric pole cages of 7m, 8.4m, 9m, 10.5m, 12m, 14m. Electric pole cages of 4m, 6m, 8m, 10m, they are assembled to form a combination of 18m, 20m, 22m, 24m for river crossing works.

SEWER CAGE WELDING MACHINE

Steel after being cut according to specifications is put into the welding machine to shape the steel core for each type of concrete circular sewers. The machine system automatically operates, applying Inverter technology in combination with PLC through specialized software in order to have high economic efficiency and maximize labor savings in the manufacturing process. The most commonly used machine systems: Sewer cage welding machine specializes in welding and shaping steel cages (12 bars of longitudinal steel) to manufacture circular sewers of types of D300mm to D1200mm with the length of 4m Sewer cage welding machine specializes

SQUARE PILE CAGE WELDING MACHINE

Steel after being cut according to specifications is put into the welding machine to shape the steel core for each type of concrete square piles. The machine system automatically operates, applying Inverter technology in combination with PLC through specialized software in order to have high economic efficiency and maximize labor savings in the manufacturing process. The most commonly used machine systems: Square pile cage welding machine for PC Bar steel Ø 7.1 ÷ Ø 10.7, connecting by hoop iron Ø 3 ÷ Ø 5 to manufacture prestressed concrete square piles of types of D200mm to D400mm, with the length

TENSION MACHINE FOR TUBE PILES AND ELECTRIC POLES

After feeding concrete into the mold, the tension machine will be used to prestress the PC Bar or PC Wire steel before going through the centrifugal rotation stage. The machine system operates completely automatically by hydraulic system, which allows setting tension, movement, up and down route, etc. suitable for each type of product. Control and display tension on LCD screen. The most commonly used machine systems: Tension machine 25 tons to 60 tons specialized in manufacturing prestressed square piles of types of V200mm to V400mm. Tension machine 150 tons specialized in manufacturing electric poles and tube piles up to

CLAMPING AND PICKING SYSTEM (TX + TF)

The specialized clamping and picking system (TX+TF) is used in combination with the crane to serve the stages of clamping + picking + lifting + lowering + moving the centrifugal molds. The most commonly used TX+TF systems: TX+TF for the manufacture of tube piles (electrical poles) D300 ÷ D600, L=14m. TX+TF for the manufacture of tube piles D300 ÷ D600, L=18m. TX+TF for the manufacture of tube piles D500 ÷ D1000, L=30m.

CLAMPING SYSTEM (TX)

It is specifically used in clamping centrifugal molds to serve in the manufacture of centrifugal concrete tube pipes (electrical poles), etc... The clamping system (TX) is specialized in combination with the crane to serve the stages of clamping + picking + lifting + lowering + moving the centrifugal molds. Clamping the whole mold with concrete for quick and safe operation in manufacture. The most commonly used TX systems: TX for the manufacture of tube piles (electrical poles) D300 ÷ D600, L=14m. TX for the manufacture of tube piles D300 ÷ D600, L=18m. TX for the manufacture of tube piles

VACUUM SYSTEM FOR SEPARATING TUBE PILES

It is specialized in separating tube piles from centrifugal molds, creating safety and aesthetics on the product surface, this is the final stage of the manufacturing process Using a vacuum system to separate the product is the most optimal method, it creates a smoothness in the process to minimize cracks, scratches, etc. on the product surface. The system is applied in the manufacture of tube piles, the stage of separating the product from the centrifugal mold The current popular vacuum extraction structure: Serving the product separation of pipe pile products D300 -: - D600, L = 12m -: -

LONGITUDINAL MOLD CHAIN CONVEYOR

The mold conveyor system is used for mold transfer after the product is separated -> cleaning the mold -> installing the steel cage into the mold -> installing the holder into the mold -> to the position of loading concrete into the mold. The system operates according to programmed time in order to create safe and effective conditions for high productivity in the manufacture.

HORIZONTAL MOLD CHAIN CONVEYOR

Horizontal mold chain conveyor chain system is used to serve the stages of mold transfer for bolting -> tensioning and mold transfer for discharging bolts -> product separation. The system operates completely and continuously according to programmed time in order to create safe and effective conditions for high productivity in the manufacture.

180° MOLD UPSIDE-DOWN SYSTEM

180° mold upside-down system is used to turn the mold upside-down after the product is separated -> putting the mold on the longitudinal mold chain conveyor to carry out cleaning and installation of steel cages. 180° mold upside-down system is used to turn the mold upside-down after being cleaned -> waiting for covering after the concrete loading stage.

SYSTEM OF LIFTING & SEPARATING PRODUCTS FROM CENTRIFUGAL MOLD

The specialized separating system lifts and rotates the mold at a suitable angle to separate the product from the centrifugal mold. The system combines many stages: raising up to the appropriate height according to each type -> rotating the mold at the appropriate angle -> supporting the product -> putting the product on the roller to transfer the product to the yard. The system is applied in the manufacture of electric poles and tube piles, the stage of separating the product from the centrifugal mold.

HOLDER 80° FOR MOLD CLEANING

The specialized holder for mold cleaning rotates 1/2 mold facing down with a suitable tilt angle of 80° -> cleaning the molds, applying oil to the molds -> returning the molds to their original state -> putting the molds on the longitudinal mold chain conveyor. The specialized holder for cleaning 1/2 mold facing down is used before putting molds on the longitudinal mold chain conveyor.

CONCRETE FEEDER

The concrete feeder is a specialized device that receives concrete from the batching plant and loads it into the mold, allowing the adjustment of the appropriate loading flow for each product. The concrete feeder uses chisels to adjust the amount of concrete into the mold stably and prevent stratification in the concrete.

CENTRIFUGAL ROTARY SYSTEM

It is specialized in the manufacture of high-quality concrete structures, compacting concrete by centrifugal rotation, bringing the highest product quality... After loading concrete and prestressing on the mold, centrifugal rotation will be carried out to create concrete link with steel structure. In the production of high-quality concrete bales, concrete compaction using centrifugal rotary method brings the highest quality products today. The system operates completely automatically, the motor uses a combination of inverter system through PLC control. In order to maximize automation and the lowest power consumption. Automatic control through specialized software, allowing automatic installation: speed of rotation, number of

TENSION RELEASE MACHINE

Specialized tension release machine is used for releasing prestressing force before separating the product from the centrifugal mold in order to obtain a perfect product, minimizing product defects after the product is separated from the centrifugal mold and creating absolute safety in product recovery The machine system is completely automatically operated by a hydraulic system Các hệ thống máy thông dụng hiện nay: The 250-ton tension release machine is specialized in manufacturing pipe piles from D300mm to D600mm. The 500-ton tension release machine is specialized in manufacturing pipe piles from D600mm to D1000mm.

CUTTING AND FLANGE RING ROLLING MACHINE SYSTEM

Machine system specializes in cutting and shaping the length of the sheet tole and rolling the flange ring for the centrifugal tube pile head. The machine system operates completely automatically according to the specialized programming, using billet from rolled steel with the specifications of 1mm ÷ 5mm, the sheet of 80mm to 100mm wide. The machine system is applied to common tube piles D300 ÷ D1000.

RING INSTALLING MACHINE

Specialized machine system for installing (connecting) ring into the pile flange to complete the pile flange product before putting into the manufacture. The ring after being rolled, ribbed and flared will be pre-positioned to the flange, then it is put into the machine to form a completed flange. The machine is used by the lever arm structure combined with pneumatic force through the rolling structure for forming a completed flange.

CONTINUOUS PILE MOVING ROLLER SYSTEM

It is a specialized system for moving concrete products after being separated from the centrifugal molds to the storage yard. The system is designed according to the continuous moving type in order to increase productivity and efficiency in centrifugal concrete manufacture.

TENSION TESTING MACHINE FOR PC BAR STEEL

The machine is used to test the stamping head for PC Bar or PC Wire steel when the tension stress is reached before being put into mass manufacture. The machine uses hydraulic pulling combined with a standard steel mounting system.

PC BAR STEEL DISENGAGING EQUIPMENT

Specialized in disengaging PC Bar steel from standard reel according to specifications and put it into PC Bar steel cutting machine to cut to the required manufacturing length. The structure is manufactured according to the rotational force around the shaft with a steel guide and anti-tangle roller.

RIBBING AND FLARING MACHINE

The machine specializes in ribbing (grooving), rolling and flaring of pile flange ring before being assembled into the flange. The pressing force is created by the pneumatic system through the lever arm structure combined with the rotational force of the detail.

FRICTION WINCH AND WAGON

Specialized in transporting movable molds, combined with concrete feeder to put the amount of concrete into the centrifugal mold.